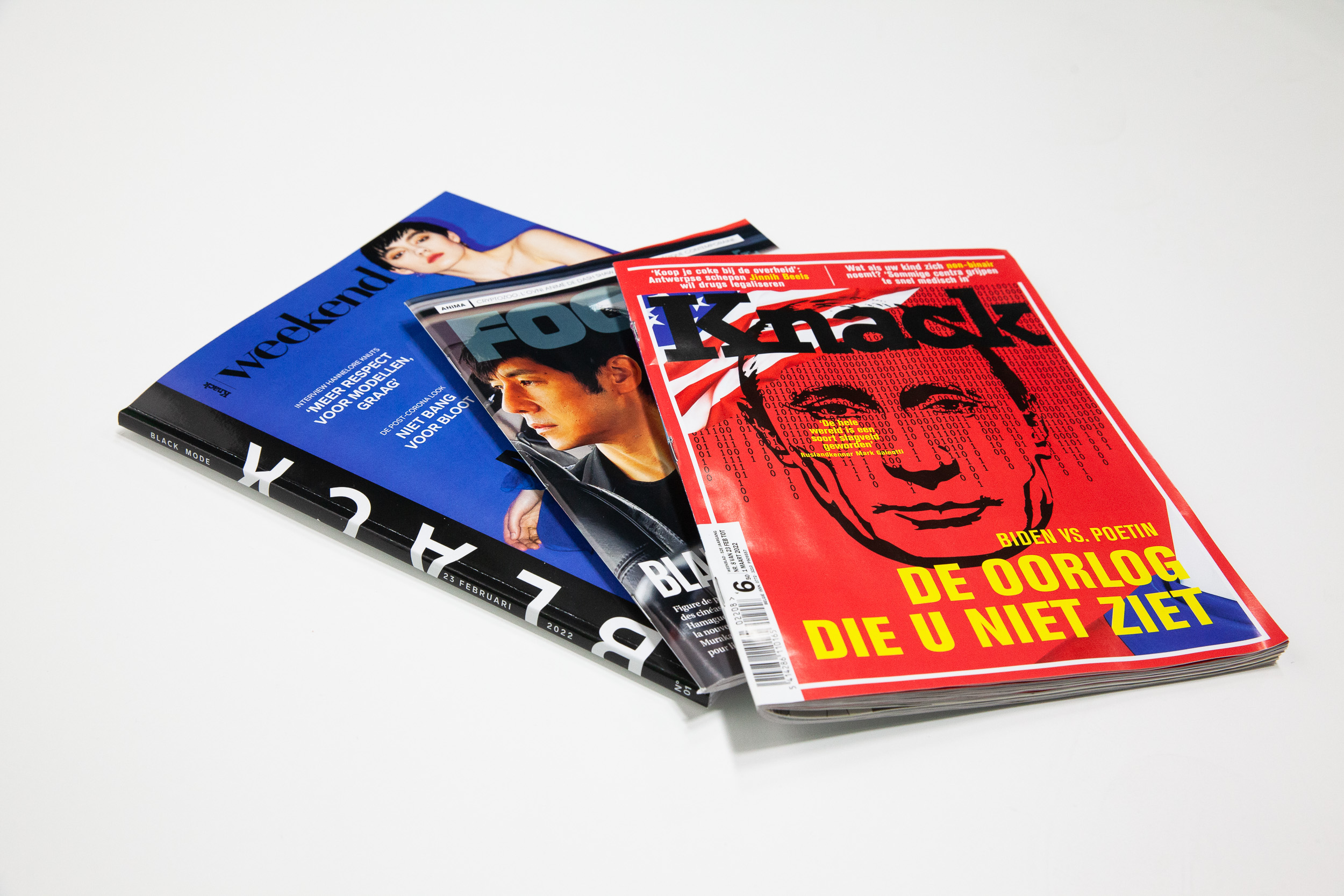

A MAGAZINE TO BE PROUD OF

In terms of handling and shipping, Roularta Printing is also a versatile and high-performance partner. Inserting cards, sticking on samples, shrink-wrapping or packaging in paper… Our packaging department combines a flexible machine park with many years of experience.

Require global shipping? Roularta Printing is recognized as a Known Consignor for air shipment of printed matter. We package and secure your printed matter under strict safety regulations so that your shipment can immediately be loaded on the plane without further formalities.

How do we make a difference

Production revealed

Creation and layout

Printing and finishing

We can fold, glue and trim in-line on the press so your product is immediately ready to be bundled and packaged. Do you require off-line finishes? We will then collect the printed sections on print rolls, reducing the risk of damage during finishing to an absolute minimum.

Handling & Shipping

THE BENEFITS OF ROTARY OFFSET HEATSET

An intense drying followed by a lightning-quick cooling fixes the ink on the paper. The result? Powerful, deep colours and a print that doesn’t run. The accelerated drying also makes it possible to print on a wide range of paper qualities and grammages.